The world of electric vehicle (EV) motors is in a constant state of innovation, with engineers focused on creating more powerful, efficient, and sustainable designs. While Permanent Magnet Synchronous Motors (PMSMs) and induction motors are the current industry standards, new technologies are emerging to push the boundaries of performance and sustainability.

Here are some of the latest advancements in EV motors:

1. Axial Flux Motors: The “Pancake” Revolution

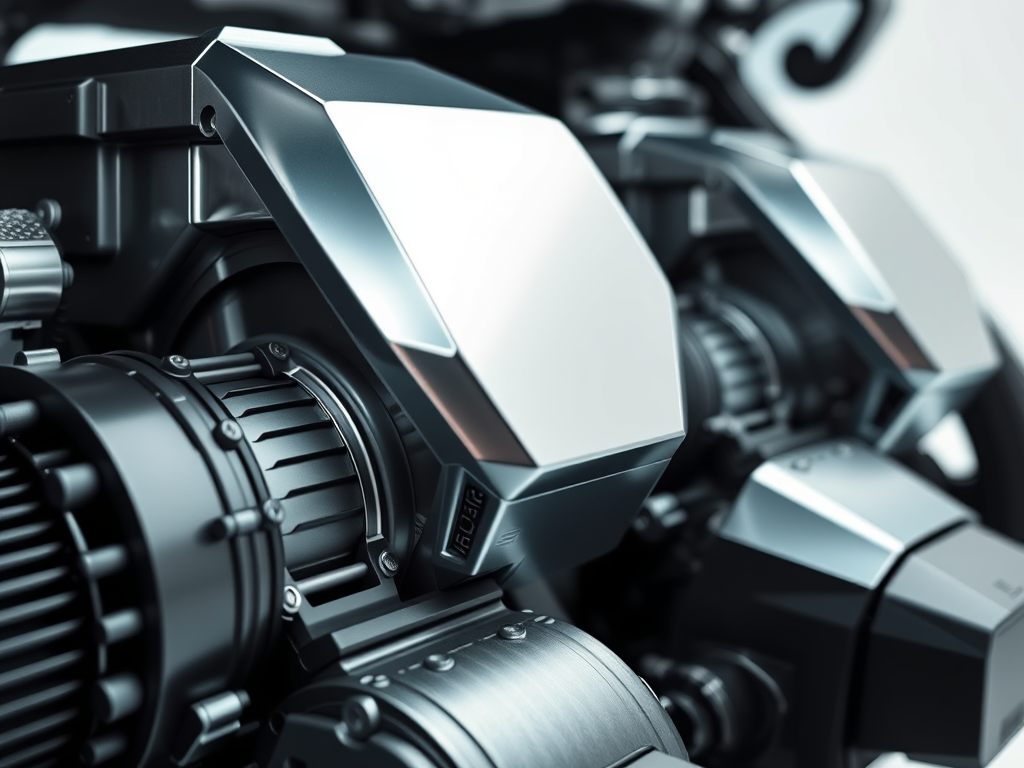

While most EV motors today are “radial flux” motors, which have a cylindrical shape with a magnetic field flowing perpendicular to the motor shaft, a new design is gaining significant traction: the axial flux motor.

- Compact and Powerful: Axial flux motors have a flat, disc-like shape, often called “pancake” motors. This design allows the magnetic flux to flow parallel to the motor shaft, resulting in a much shorter, more compact, and lightweight motor. This makes them ideal for EVs, where space and weight are critical for maximizing range and performance.

- Higher Torque and Efficiency: Axial flux motors can be up to four times more torque-dense than traditional radial flux motors. They also have shorter magnetic paths, which reduces energy loss and allows for higher efficiency. This translates to better acceleration and a longer driving range.

- New Materials: The rise of axial flux motors is made possible by advancements in materials like Soft Magnetic Composites (SMCs), which are more efficient at handling the unique magnetic flux path of these motors and are less expensive to manufacture.

2. The Move Away from Rare Earths

A major challenge for EV motor manufacturers is the reliance on rare earth metals, particularly neodymium, for the powerful magnets used in many motors. The mining of these materials has environmental and geopolitical concerns.

- Rare-Earth-Free Motors: Automakers are actively developing new motor designs that eliminate or significantly reduce the use of rare earth magnets. Tesla, for example, has announced its next-generation motor will be a permanent magnet machine that does not use rare-earth materials.

- Alternative Designs: New motor topologies, such as Switched Reluctance Motors (SRMs) and Electrically Excited Synchronous Motors (EESMs), are gaining attention because they can achieve high efficiency without permanent magnets. While some of these designs can be noisier, engineers are working on new control algorithms and designs to mitigate this issue.

3. Advanced Motor Control and Power Electronics

The motor itself is only part of the equation; the “brain” that controls it is also advancing.

- Advanced Inverters: Inverters convert the direct current (DC) from the battery into the alternating current (AC) needed by the motor. New inverter designs using materials like Silicon Carbide (SiC) are more efficient, can handle higher power levels, and are more compact, which reduces overall energy loss and improves performance.

- Smart Algorithms: Sophisticated control algorithms are now being used to manage the motor. These algorithms can optimize energy use based on real-time driving conditions, such as accelerating on a flat road or climbing a hill, to improve efficiency and responsiveness.

4. Direct Integration and New Architectures

The motor is being integrated into the vehicle in new and innovative ways.

- In-Wheel Motors: For a more modular design, some companies are developing motors that are placed directly inside the wheels. This eliminates the need for a central motor and complex drivetrains, which can free up space and provide precise torque control to each wheel.

- Multi-Phase Motors: While three-phase motors are the industry standard, some companies are experimenting with five-phase motor designs. These designs can provide more power and torque while also being more fault-tolerant, meaning the motor can continue to operate even if one of the phases fails.

Leave a comment