The American logistics industry is the backbone of the nation’s economy, but it’s operating in one of the most demanding environments in history. The days of simple truck-and-warehouse operations are over. Today, logistics leaders aren’t defined by the size of their fleet, but by the intelligence of their network.

We’re facing a perfect storm of rising fuel costs, ongoing labor shortages (especially truck drivers), tightening environmental regulations, and consumer demands for near-instant delivery. To survive and thrive in this landscape, logistics providers must ditch outdated manual processes and embrace streamlined, digital-first solutions.

The Unavoidable Challenges of US Logistics

Before diving into the solutions, it’s vital to acknowledge the pressure points currently stressing the US supply chain:

1. Cost Volatility and Capacity Gaps

Fuel price swings, fluctuating freight rates, and rising insurance premiums mean that costs can spike overnight. Simultaneously, the underlying truck driver shortage and an unpredictable global market create sudden capacity shortages, turning what should be a simple shipment into a costly scramble.

2. The Last-Mile Pressure Cooker

E-commerce has spoiled consumers. The expectation for fast, free, and fully visible delivery—often same-day or next-day—puts immense pressure on the “last mile” of the journey. Urban congestion only compounds this, turning city deliveries into a time-and-money drain.

3. Regulatory and Sustainability Demands

Compliance is getting more complex. From new Electronic Logging Device (ELD) mandates to stricter emissions standards, carriers face increased administrative and financial burdens. Companies must now demonstrate a commitment to sustainability, making “green logistics” not just a moral choice, but an operational necessity.

Streamlined Solutions: The Digital Transformation

The industry’s answer to these challenges is not more trucks, but more technology. Logistics providers are using digital intelligence to streamline every touchpoint, creating efficiencies that cut costs and improve service simultaneously.

1. AI-Driven Route Optimization and Fleet Intelligence

AI is the brain that powers the modern logistics network. It moves past static GPS to dynamic routing, constantly recalculating the fastest, most fuel-efficient sequence of stops based on live data.

- Fuel Savings: By minimizing mileage and avoiding congestion, AI drastically reduces a carrier’s largest variable cost: fuel.

- Driver Retention: A predictable, optimized route creates a better experience for drivers, helping to address the industry’s critical labor shortage problem.

- Predictive Maintenance: IoT sensors on trucks feed data into an AI system, allowing it to predict component failures before they happen. This means fewer unexpected breakdowns, maximizing fleet uptime and reducing costly delays.

2. End-to-End Visibility and Digital Twins

Shippers, carriers, and customers all need to see the same information at the same time. Digitalization solves the problem of data silos.

- Control Tower Solutions: Modern Transportation Management Systems (TMS) act as a “control tower,” aggregating data from IoT sensors, partner systems, and public feeds (like weather). This gives shippers real-time, end-to-end visibility of their entire supply chain, allowing for proactive intervention if a disruption occurs.

- Customer Trust: Real-time tracking and automated ETA notifications satisfy the customer’s demand for transparency, reducing the volume of “where’s my order?” calls and enhancing brand loyalty.

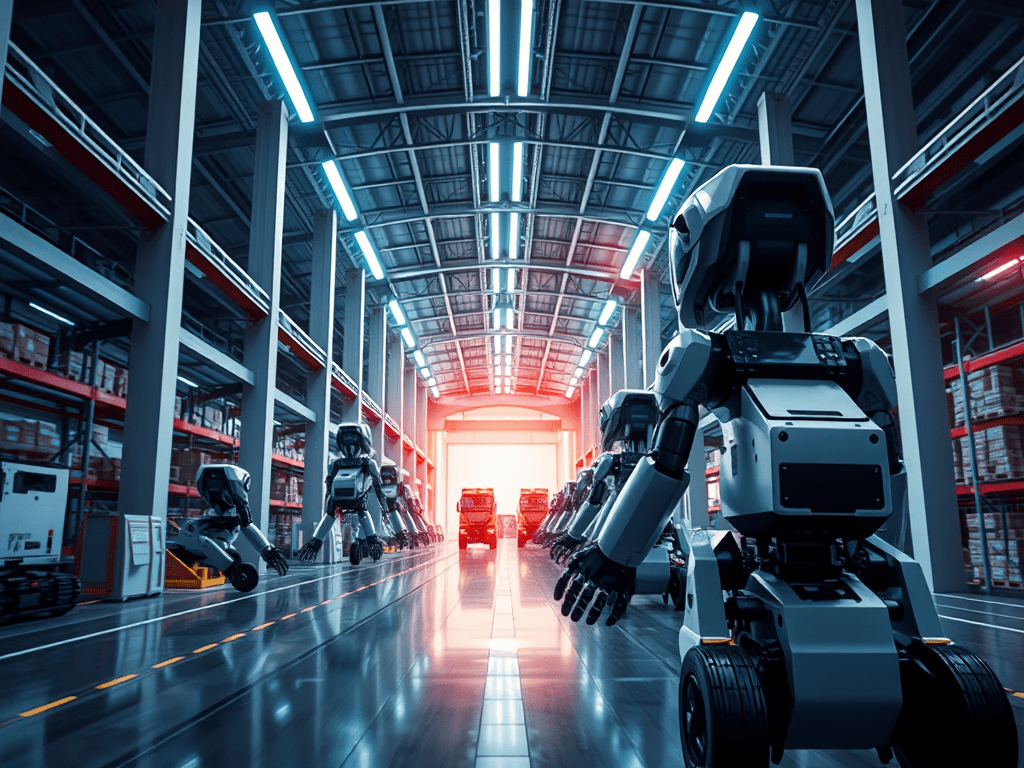

3. Automation for Labor Gaps

With labor shortages persisting, the focus is on automating repetitive, low-value tasks.

- Warehouse Robotics: Automated Guided Vehicles (AGVs) and sorting systems are becoming standard in fulfillment centers, increasing picking speed, reducing errors, and allowing human workers to focus on more complex, value-added tasks.

- Hyperautomation in Back-Office: Robotic Process Automation (RPA) is used to automate administrative tasks like freight auditing, customs clearance documentation, and invoice reconciliation, freeing up skilled personnel and drastically improving data accuracy.

The Takeaway: Partner with a Digital Master

In this transformative era, the most successful logistics companies are those that prioritize efficiency over volume, and intelligence over muscle. They are the ones who can offer truly streamlined solutions by treating data as their most valuable commodity.

For American businesses, choosing the right logistics partner means selecting a firm that has already made the commitment to this digital future. Don’t settle for a provider who is catching up; partner with one that is already leading the way with AI, automation, and end-to-end digital visibility.

The future of logistics is not about the road—it’s about the network. Make sure your business is connected to one that’s built for tomorrow.

Leave a comment